HSS to HSS Connections: A Comprehensive Introduction

In the realm of structural engineering, the significance of connections cannot be overstated. They are the glue that holds steel structures together, providing not only stability but also the crucial ability to transmit loads effectively.

Let’s take a closer look at what is behind the whole area of HSS structures. Which sections are HSS? All the types that are not open (that was quite easy, right?)

Standard HSS shapes: What tube arsenal is available for a structural engineer's design?

- RHS - rectangular hollow section

- SHS - square hollow sections

- CHS - circular hollow sections

- Exceptionally even elliptical

Use of HSS members: We can use HSS members everywhere, but the most common applications are:

- Columns

- Braces

- Trusses

- Curved Beams

How are the tubes made?

The tubular members are manufactured in two different ways:

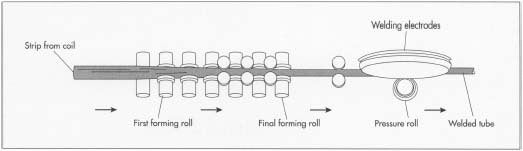

- Colled-formed / rolled + welded – the tubes are created by bending sheet metal into the required shape and then welded into the closed section.

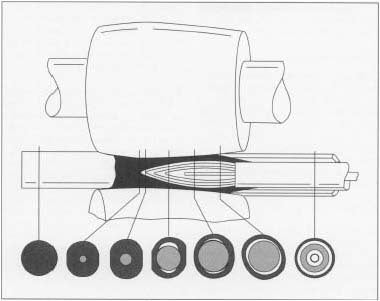

- Continuous milling – the basic material is heated to white-hot and molded into a cylinder and then a bullet-shaped piercer point is pushed through.

Advantages of HSS members

-

Aesthetics

Clearer look than the open sections

-

Economical

Weigh less, cheaper per meter and less surface area with lower finishing costs

-

Great static parameters

It offers 200 times more torsional resistance than open sections (I, C, L, and T shapes) and greater compression capacity for the same unbraced length.

-

Usable as a jacket for the concrete column (for increased axial capacity)

HSS members can be effectively employed as jackets for concrete columns. This application significantly increases the axial capacity of the column, making it a valuable choice in structural engineering.

-

Wide range of standard sizes

HSS members are available in a diverse range of standard sizes. This versatility allows for greater design flexibility, making it easier to tailor structural elements to specific project requirements.

What are the maximum standard sizes available these days?

An answer could be found in the new world’s largest continuous ERW mill just recently built in Chicago as the pride of US steel pipe and tube manufacturer Zekelman Industries. Until now, the maximum HSS size provided in the US was 16″x16″x5/8″ (406x406x16 mm).

In this new mill, they increased the maximum tube sizes up to:

SHS – 22″x1″ (559×25 mm)

RHS – 34″x10″x1″ (864x254x25 mm)

CHS – 28″x1″ (711×25 mm)

Disadvantages of HSS members

- Not ideal as flexural (bending moment-resisting) members due to more steel usage compared to an equivalent I-shape section.

- Bolted connections are difficult to install since the section is closed

Design codes and manuals dealing with HSS connection design - main regional guidelines:

- AISC 360 - Chapter K

- AISC Design Guide #24: Hollow Structural Section Connections

- EN 1993-1-8 - Chapter 7

- CIDECT Design Guides (International Committee for the Development and Study of Tubular Structures)

- HSS Design manual, Volume 3: CONNECTIONS AT HSS MEMBERS (Steel Tube Institute), etc.

Advantages of HSS connection solved in IDEA StatiCa

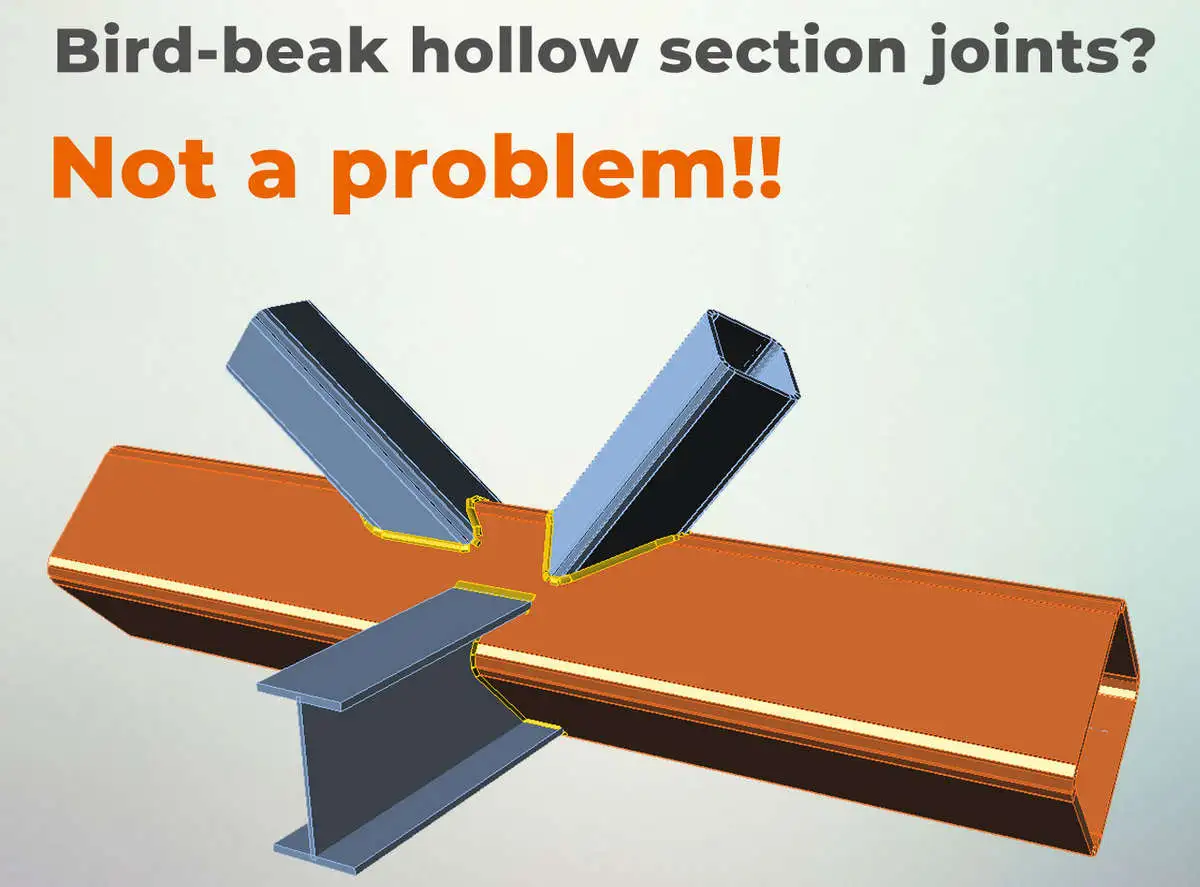

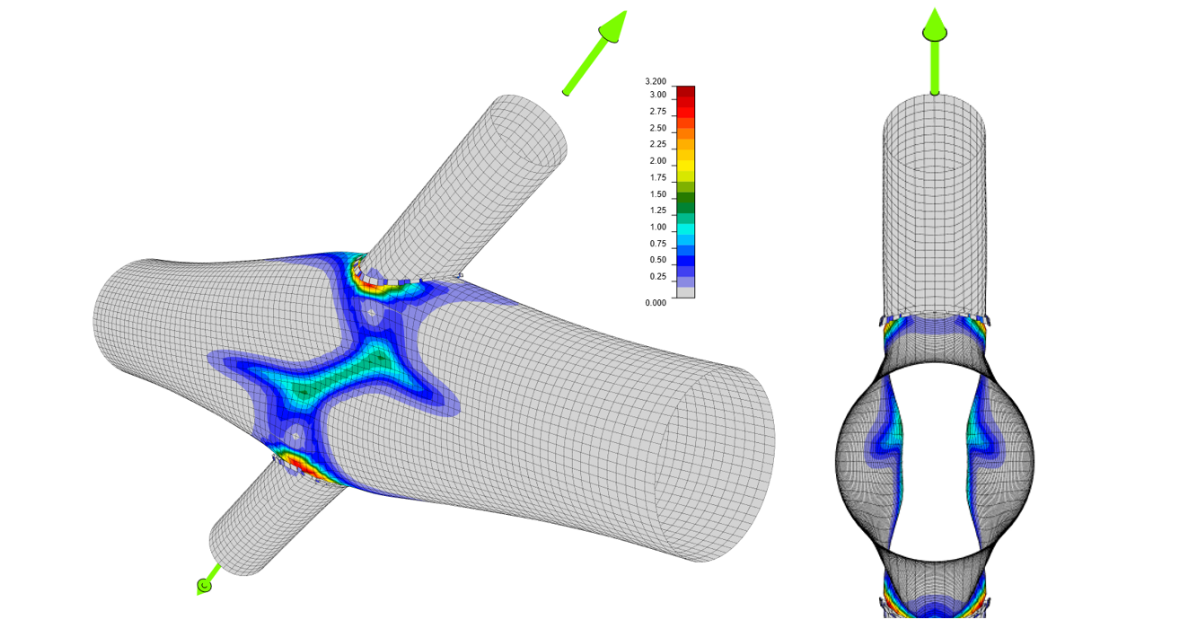

For multiplanar hollow section connections, the designer applying the code provisions needs to make assumptions-heavy approximations in order to calculate them, while there is always the danger that there are configurations that are simply not covered by the code provisions. One such example is the bird beak type of connection, especially when the incoming members are in sections.

The underlying CBFEM model from IDEA StatiCa can safely be extended to calculate multiplanar hollow section connections while maintaining the same level of accuracy as in the case of uniplanar hollow section connections. Even the bird beak type of connection can easily be modeled and calculated without requiring any special action to be taken by the designer.

What tools can be used for HSS connection design?

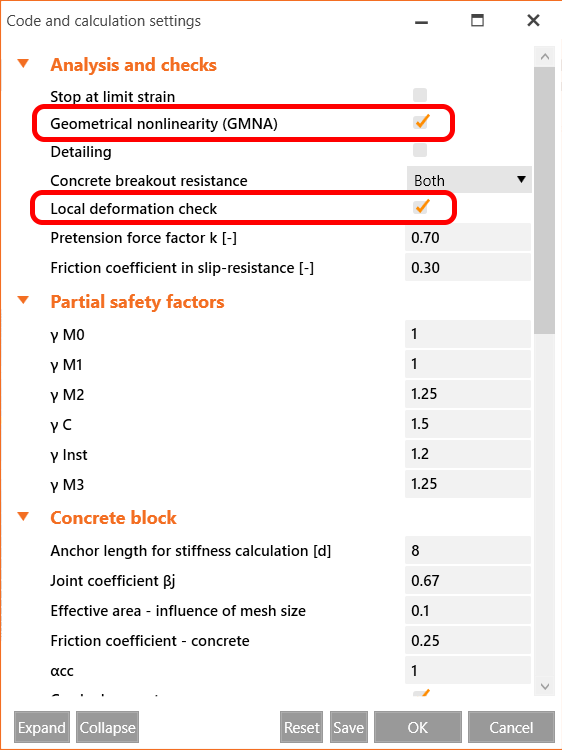

The HSS connection design and analysis couldn’t be precise enough without the GMNA (geometrically and materially nonlinear analysis)that can calculate even the most challenging case with slender walls governed by high local deformations. What was it developed for and when to use it? All the necessary information is summed up in one of the previous blog posts dedicated to this topic, below.

If you’re looking for some inspiration for circular hollow sections, you could be interested in these webinars dedicated to CHS bracing member connection and to 3D multimember connection combining CHS and SHS profiles.

In order to get a better understanding of Sample Designs and Case Studies relating to HSS to HSS connection, please click here.

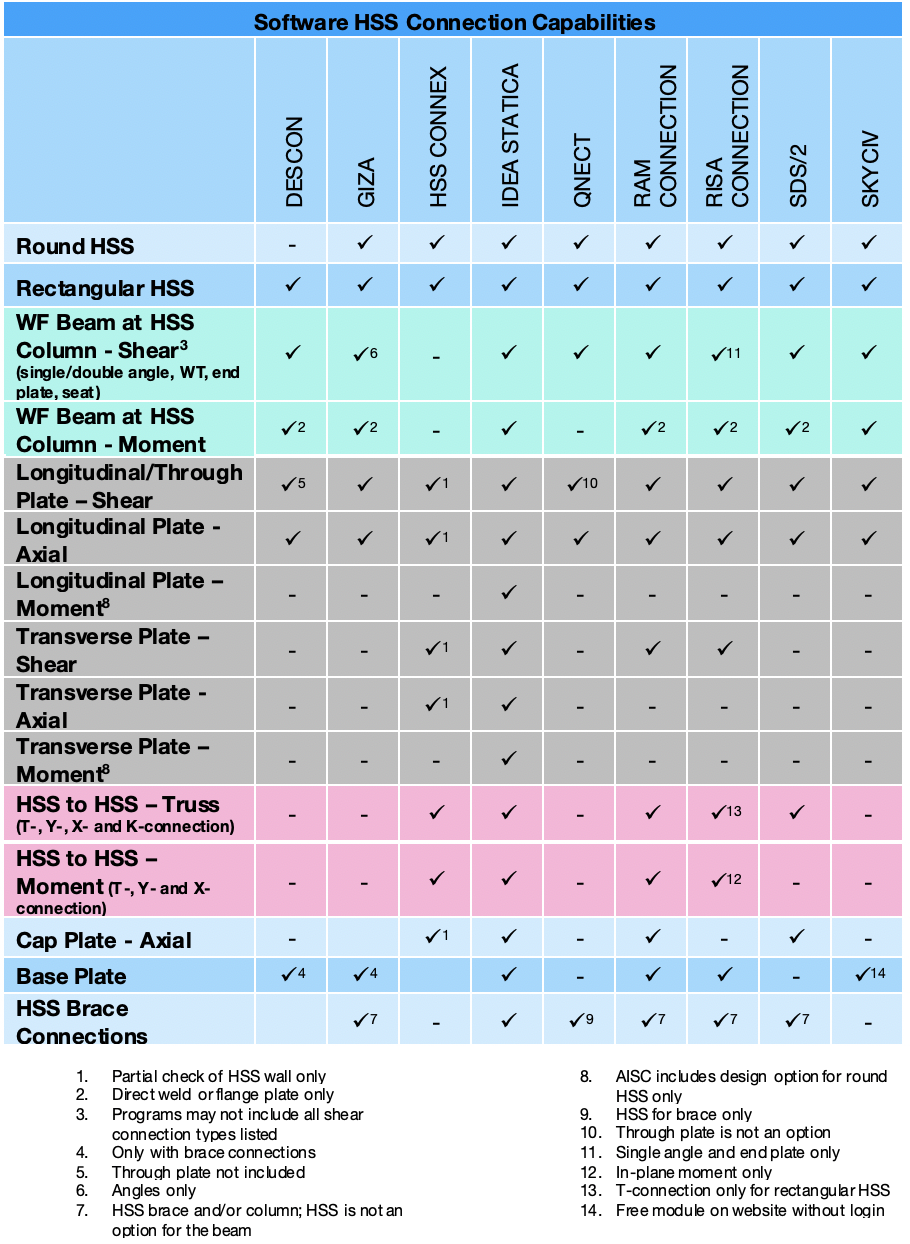

In a recent article by the Steel Tube Institute, which focuses on contemporary software tools for HSS connections, a comprehensive examination of various connection design applications in the market was conducted. The IDEA StatiCa Connection app stood out prominently as the sole tool rooted in the FEA method, enabling it to model a wide range of connection topologies. Additionally, this overview identified IDEA StatiCa as the sole tool that met all the assessed criteria.

What kind of obstacles can appear during the design?

Quite often overlooked mistakes or imperfections in design could be caused by missing checks for hollow member local buckling failure. For users of IDEA StatiCa Connection, this is an easy task since there is a simple check box embedded in the setup dialog. With this feature turned on, the local deformation check is contained by the connection analysis.

The specialties related to HSS connections were also specified in our Theoretical background dedicated to joints of hollow section cross-section members.

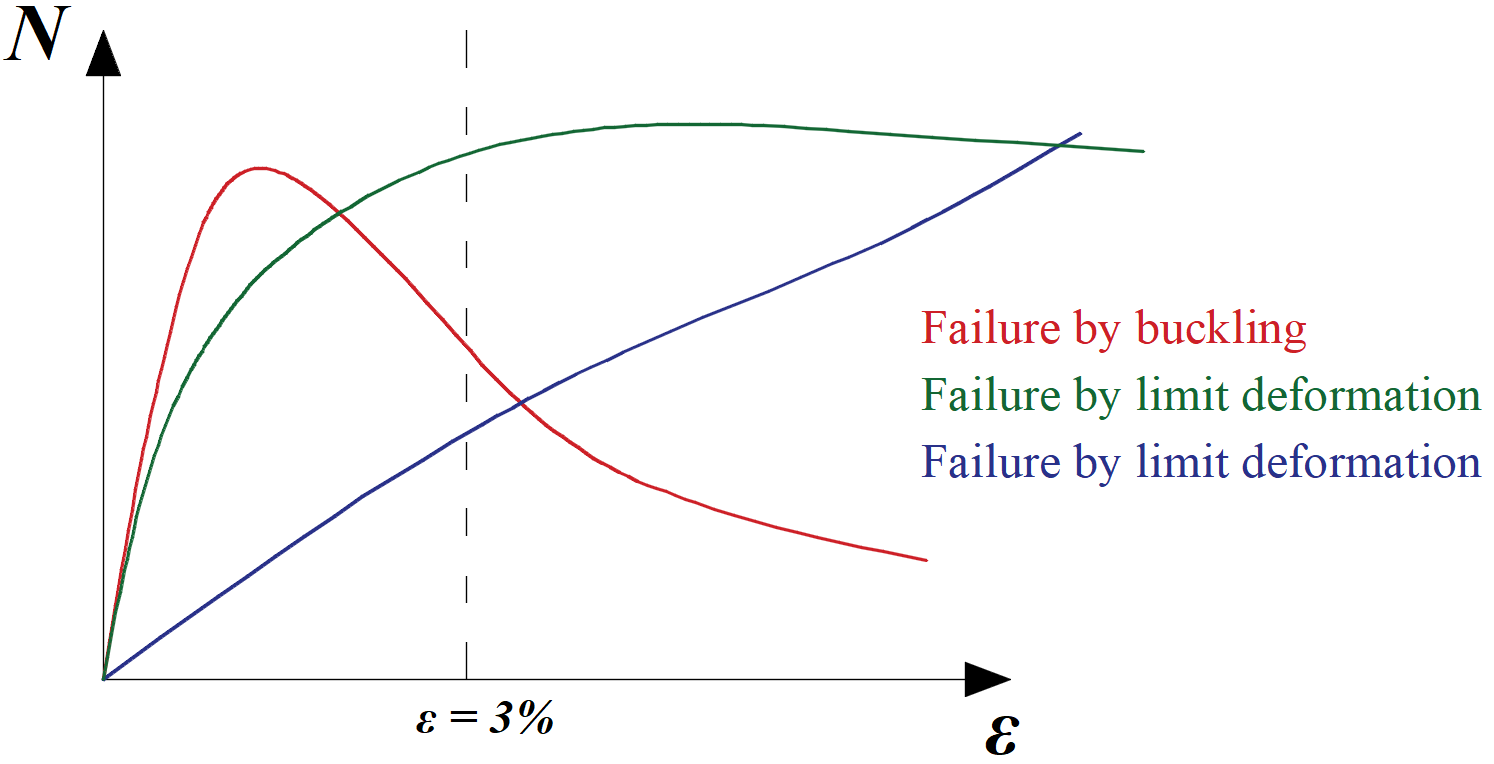

Besides the local deformation issue, we can find there is an important difference between the failure modes of thin-walled and standard hollow section members:

(red line – thin-walled members, green line – standard members in compression, blue line – standard members in tension)

5 Key Takeaways:

- The 'Connect to' feature in IDEA StatiCa allows users to easily browse through dozens of designs for HSS-to-HSS moment connections. The suitable designs for the specific geometry are displayed in seconds

- Users can store their own designs in the Connection browser window and easily access them later.

- IDEA StatiCa provides completely finished sample projects that users can download from their support center.

- CIDECT Design Guides (International Committee for the Development and Study of Tubular Structures)

- Users can download finished sample projects from the IDEA StatiCa Support Centre