UK office of IDEA StatiCa s.r.o.

Email: info@ideastatica.uk

Phone: +44 (0) 20 3579 9397

About IDEA StatiCa

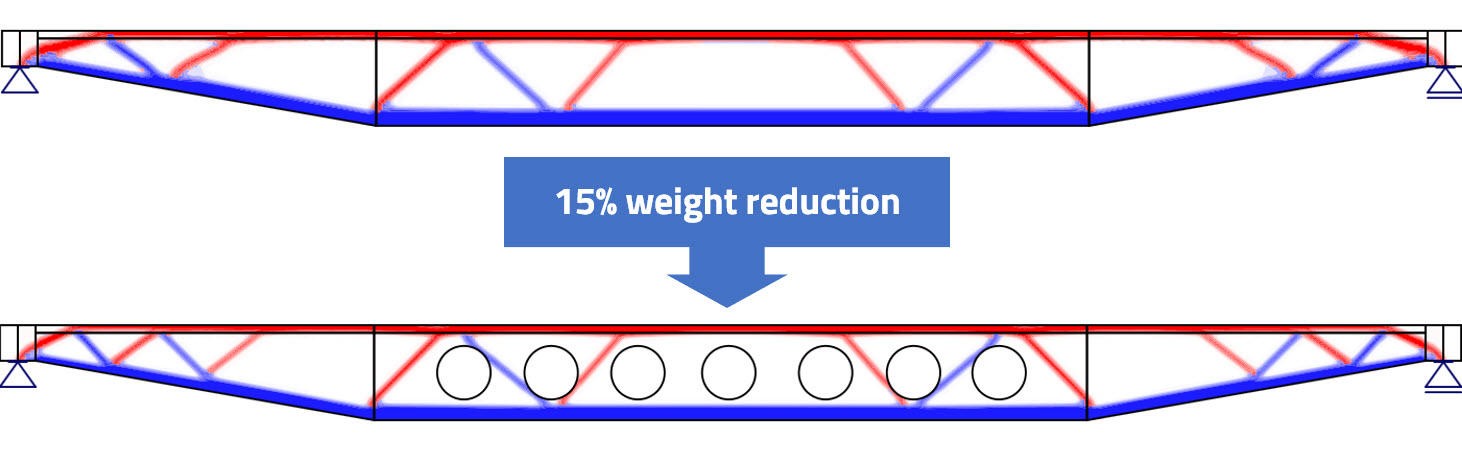

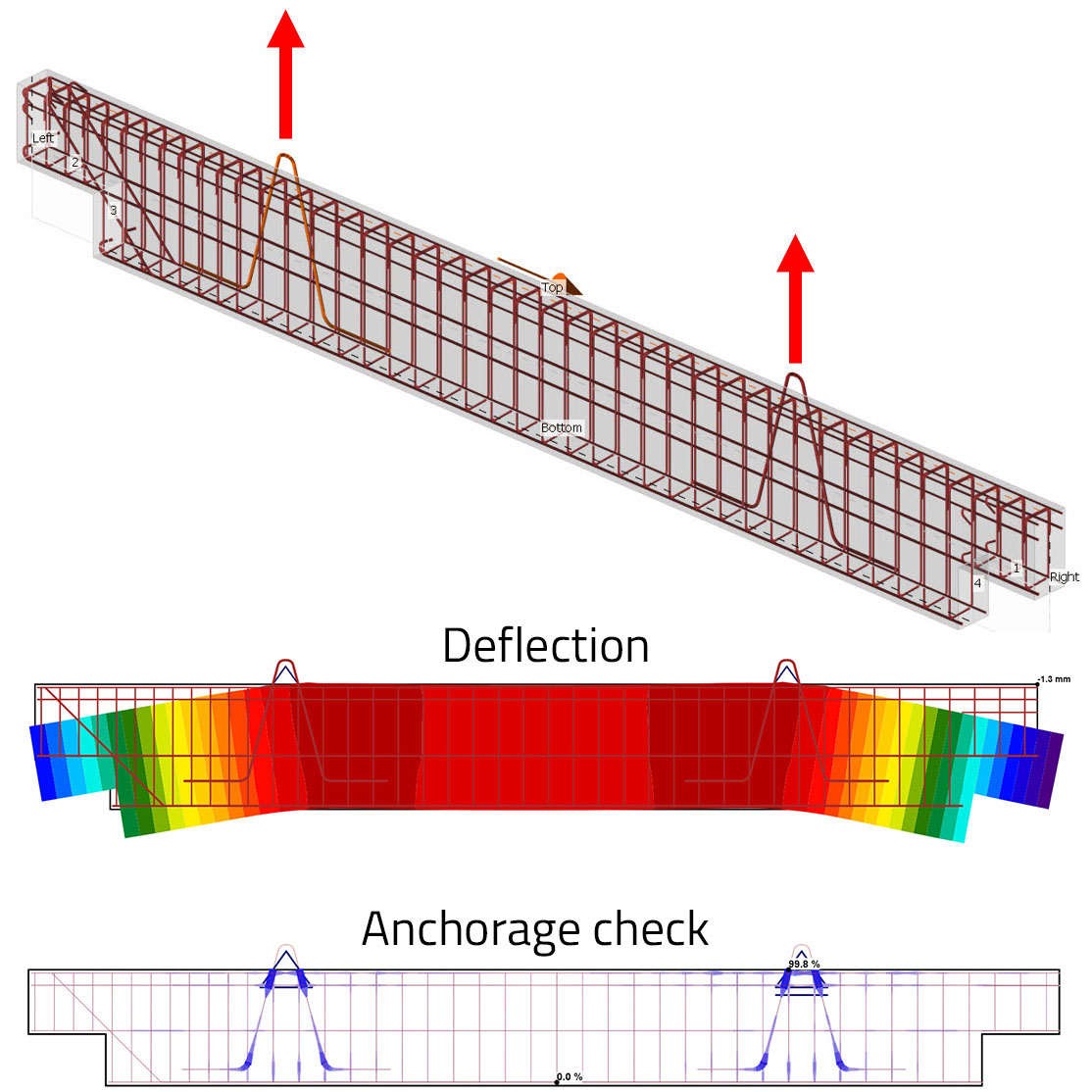

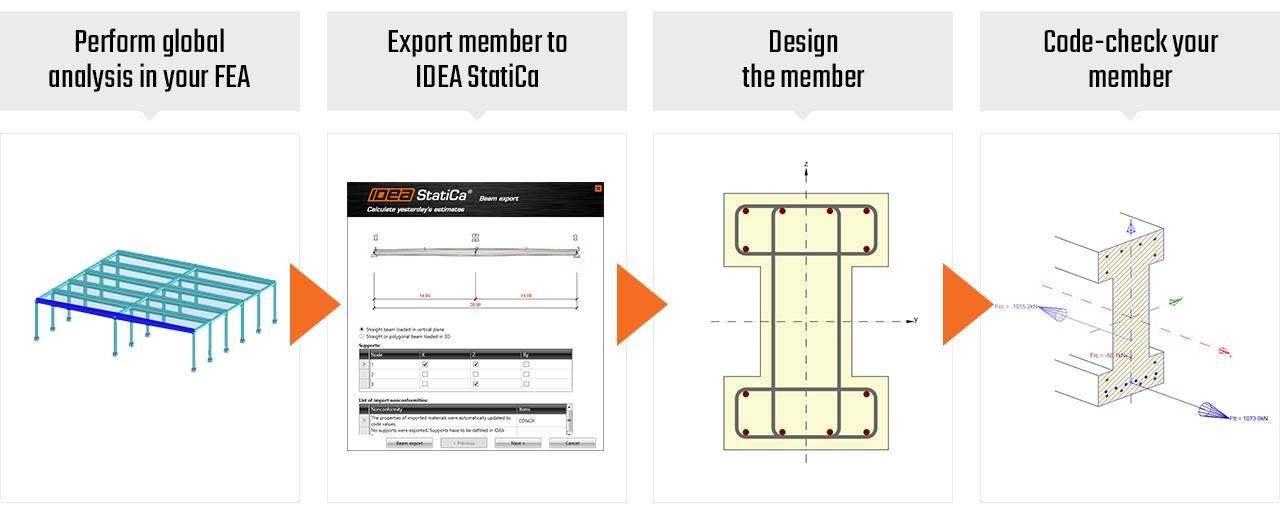

We develop software for structural engineers and detailers. Our development team researches, tests, and applies new methods of analyzing the behaviour of structures and their members. Based on this, we created IDEA StatiCa – software that enables engineers to work faster, evaluate requirements of the national code thoroughly, and use the optimal amount of material. For us, creating software is a way to contribute to making every new construction around the world safer and cheaper.