Gusset plates are steel components used in construction and engineering to strengthen connections between structural elements, distribute loads evenly, and enhance stability.

This article explores the key aspects of designing gusset plates, specifically emphasising tension and compression members. We utilize IDEA StatiCa to streamline the process and provide valuable knowledge for engineers. Join us on this journey through gusset plates to improve your understanding of structural engineering.

Members in tension in Gusset Plates

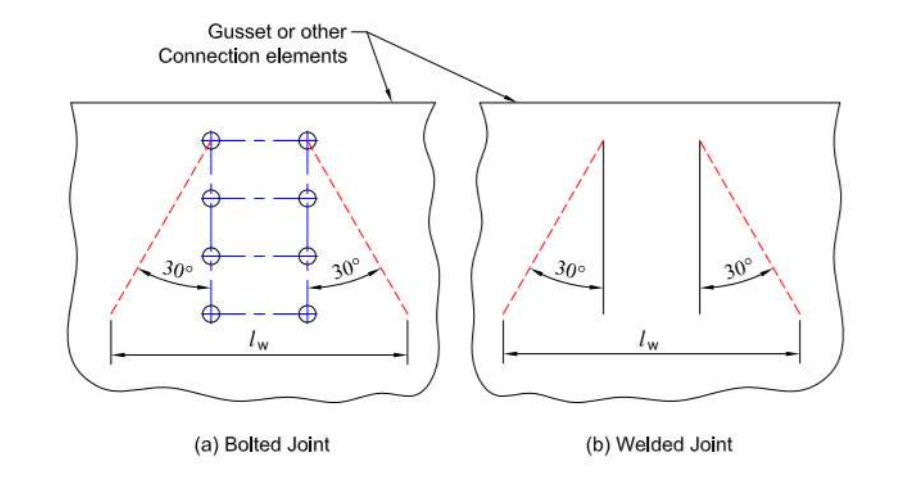

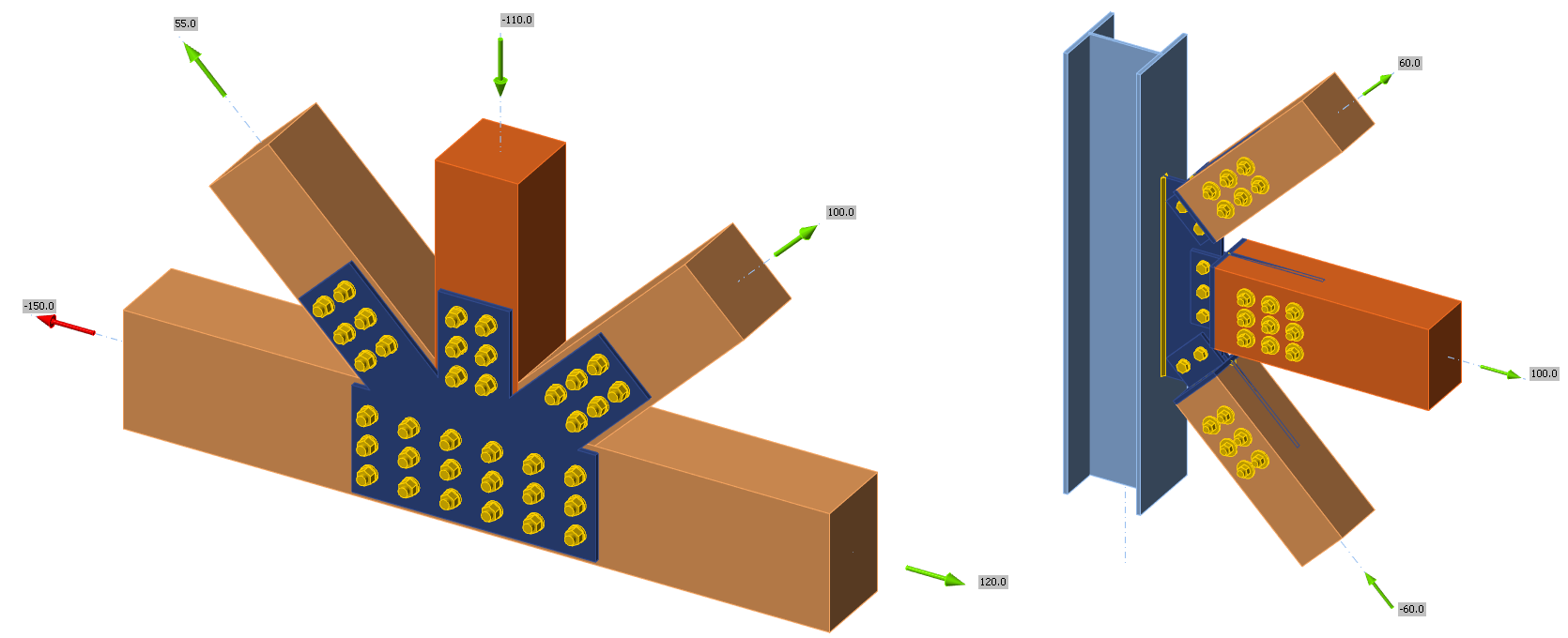

This is how the Whitmore section looks on a build structure:

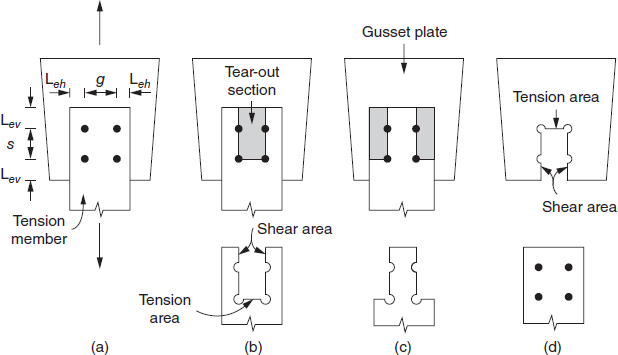

Another aspect you should consider is block shear collapse in joints. This involves both shearing and tensioning elements, and it`s covered in design regulations. Designers must evaluate all possible paths for shearing collapse within the bolt grids (as shown in the illustration – following AISC 360 Section J4.3).

You can find one nicely prepared example of block shear resistance assessment in this verification article.

Members in Compression

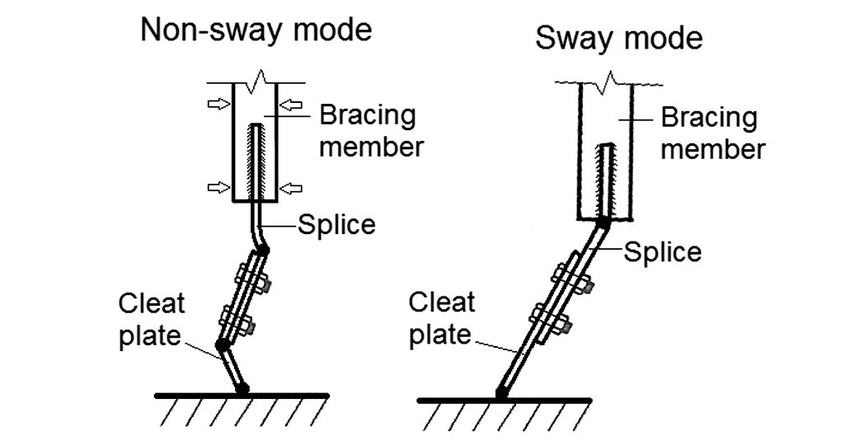

When it comes to compression members, designing gusset joints can be a whole new ball game. While we still need to examine the various shear failure modes, the issue of buckling becomes significantly more significant.

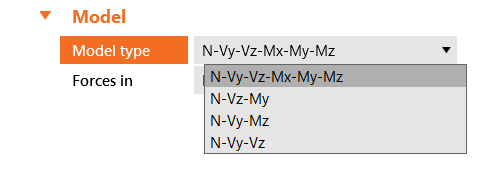

When designing the compression member, it is important to consider whether it can move out of the gusset plane or not. This will impact the way it fails and where the plastic hinges are located on the gusset plates. In IDEA Connection, you can easily specify this behaviour for each member by choosing the appropriate Model type property.

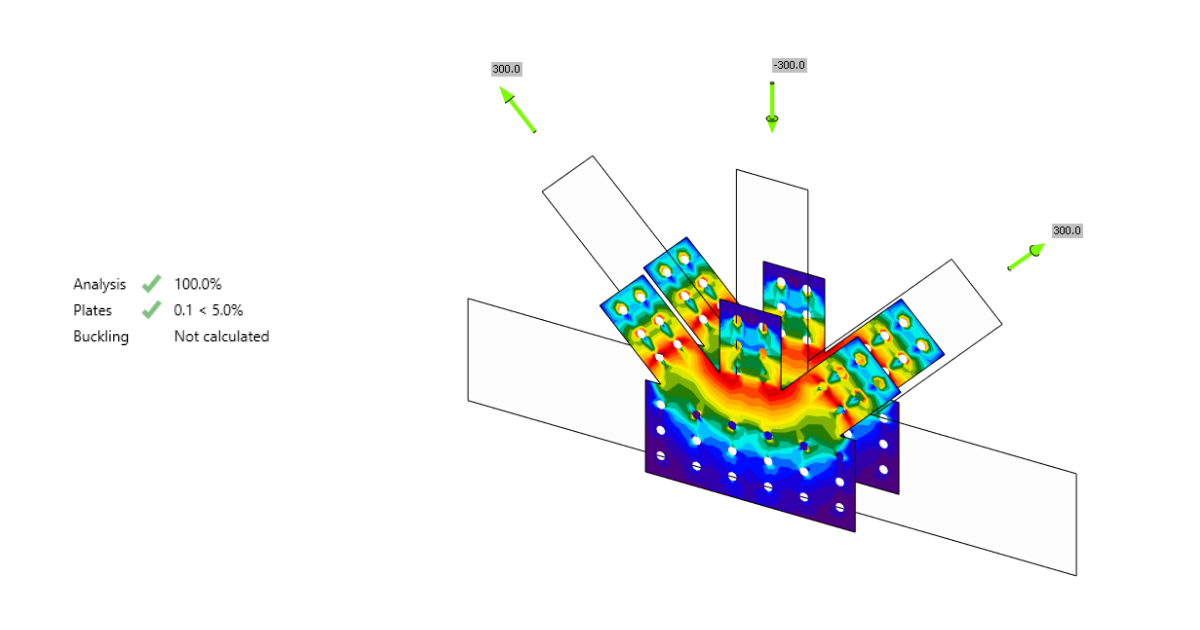

The failure modes for these two different situations are shown in the following figure.

You can also solve this problem analytically. However, that can be time-consuming when considering each joint arrangement. The designer would probably prefer to save time and meet the deadline by avoiding this situation and adding stiffeners. While this is an understandable approach, it can be costly.

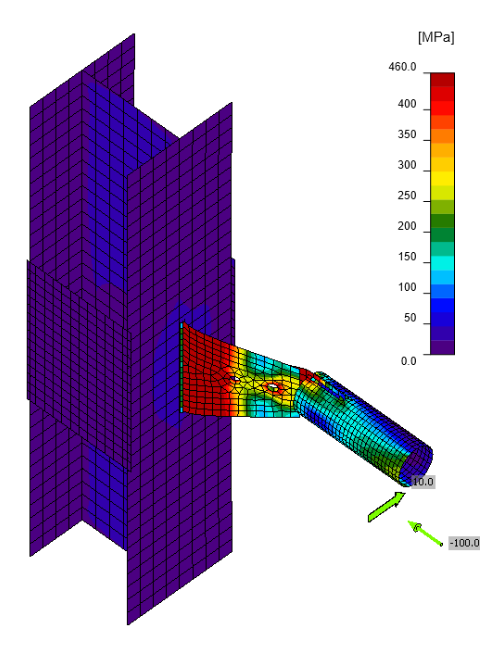

On the other hand, IDEA StatiCa Connection solves this time-consuming process by conducting a buckling analysis. This analysis is a fundamental part of the software. It can be done with a click of a button. It presents a user-defined number of buckling shapes and their corresponding critical factors. This allows the designer to assess the behaviour of the gusset using visual tools. As a result, eliminates the need for uncertain assumptions.

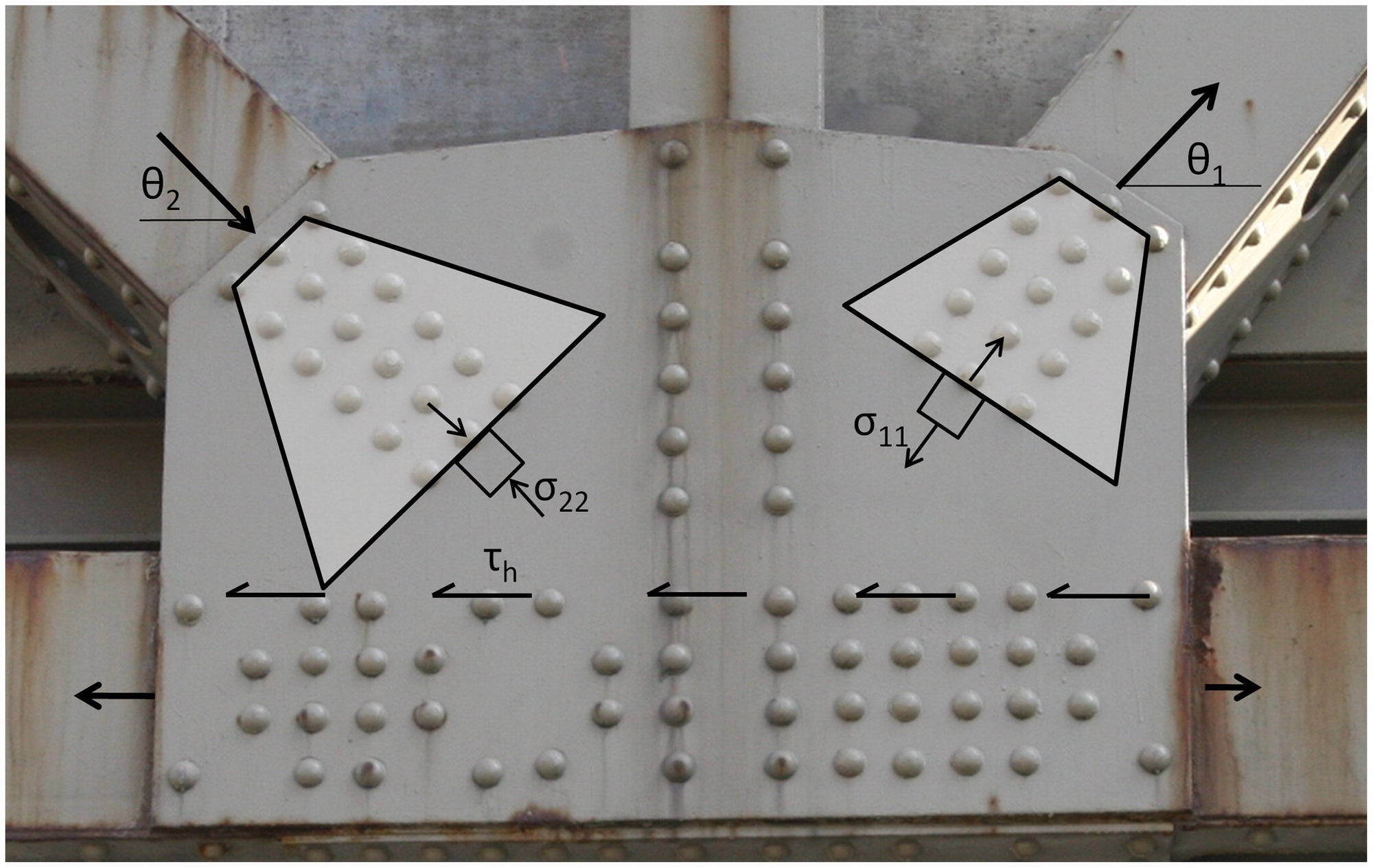

Research into Gusset Plates

When considering IDEA StatiCa, the software does not work with guesswork. All the techniques are backed by real-world data and extensively tested using numerical models developed in partnership with renowned universities worldwide.

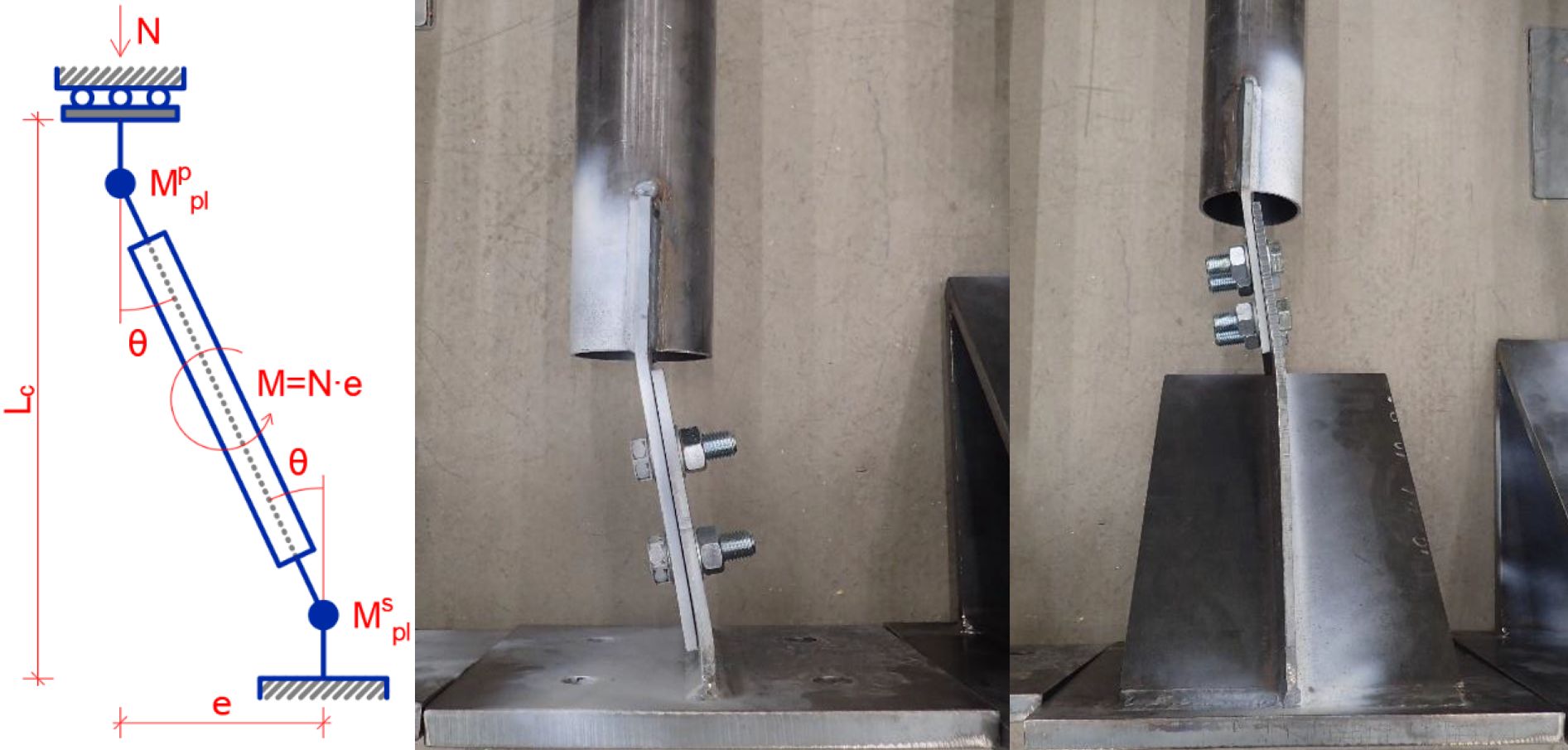

Additionally, one such research was that dedicated to the gusset plate connection design. The results of the tests were compared with the CBFEM modelling with a very good correlation. Here you can find our verification article with the outcomes of the research. This demonstrates the accuracy that IDEA StatiCa provides to your projects and leaving no space for guesswork.

How to be Effective Competitive

While cost estimation is a crucial aspect of every engineering project, accurately calculating connection costs can be challenging. In the IDEA StatiCa connection, the cost is determined as you model the connection. This provides comprehensive cost management. Gain insight into utilising this functionality by reading the following article.

Furthermore, estimating expenses can become intricate to determine the cost for each interaction in the present era. The IDEA application conveniently provides this information as a bonus. This article presents essential guidance on utilising this functionality effectively into your projects.

Another typical use of Gusset Plates

Civil engineering workshops have greatly benefited from the introduction of CNC machining. It has revolutionised the way gusset plates are used to connect steel and timber members. Instead of creating intricate designs for the ends of the members, a simpler solution is now available via IDEA StatiCa – a steel plate with pre-drilled holes. The timber members are also prepared with CNC-machined holes and grooves, and the joint is ultimately secured using steel pins and bolts.

The next step in the development of structural design involves merging different building materials and utilising their strengths in appropriate areas. This led to the creation of hybrid structures that combine timber and steel. Aside from their inherent aesthetic appeal, there are numerous advantages to utilizing them. This includes cost savings, improved fire safety, and a smaller environmental impact.

For those, interested in steel-to-timber design, read more about the timber connections solved in IDEA StatiCa Connection in our support centre.

IDEA StatiCa is proud to be in the front line for the connection and structural member design. If you have an idea of how the gusset plate design could be improved, let us know.