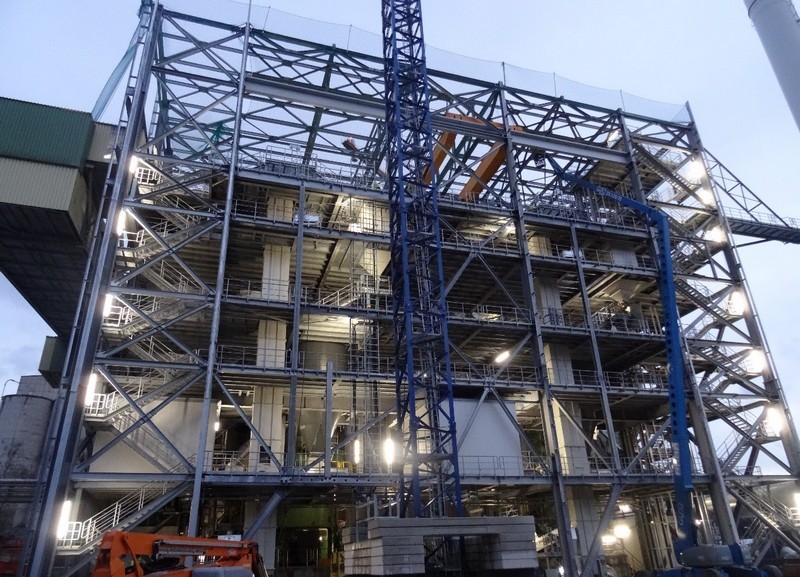

Cement Production Plant in Burglengenfeld / Germany

by SDENG

PLANNING PERIOD: 2016 to 2017

YEAR OF CONSTRUCTION: 2016 to 2018

TOTAL WEIGHT: approx. 9000 tons.

HEIGHT: approx. 140m

SCOPE OF DESIGN: 2 raw mills with transport, Filter, Preheater tower, IDfans

CONSULTANCY: http://www.kottmann-engineering.com

CLIENT: HeidelbergCement Group

About the project

The plant belongs to HeidelbergCement, one of the world’s largest building materials companies (with the takeover of the Italian cement producer Italcementi, HeidelbergCement became the number 1 in aggregates production, number 2 in cement, and number 3 in ready-mixed concrete). It is situated in Burglengenfeld, a town in the district of Schwandorf, in Bavaria, Germany. In 2015, HeidelbergCement has decided to modernise its Burglengenfeld cement plant, and IKN was awarded a contract for engineering, supply and installation to upgrade the pyro line to 4000 tpd – from raw meal feeding to clinker discharge. The contract included integration engineering, supply and installation of add-on components for the raw meal grinding plant. The upgraded kiln line features state-of-the-art technology in order to reach the targeted production level and to comply with future emission limits.

Challenges & Workflows

In the very early stages of the project, the design team of SDENG has encountered many challenges that made the use of Tekla Structures and IDEA StatiCa the most lucrative choice. Firstly, minimum cost solutions had to be achieved in a small amount of time due to the fast production process of the fabrication shop which was working in parallel with the design team. So while the design team would be calculating the connections of a specific part of the structure, the shop would be working on the previous one; so it had to be provided with all needed data in order not to pause steel production and finally delay the project.

One additional challenge was to provide precision results in order to avoid, as much as possible, any corrections by the checker of the project, which would result in several revisions to the fabrication drawings and delays. Subsequently, our team had to calculate a vast amount of connections using all possible load cases which included loads on all three axes (tension, biaxial shear, biaxial moment, torsion) as well as buckling analysis of the connections’ members. Due to the fact that the software available by that time was not capable to calculate all of these combinations in a 3D interface, many of these had to be calculated with estimations and hand-calculations. Additionally, static solutions without the use of FEM could not be as satisfactory as nowadays’ requirements so the obvious solution is the use of a ‘tool’ that can solve all these challenges.

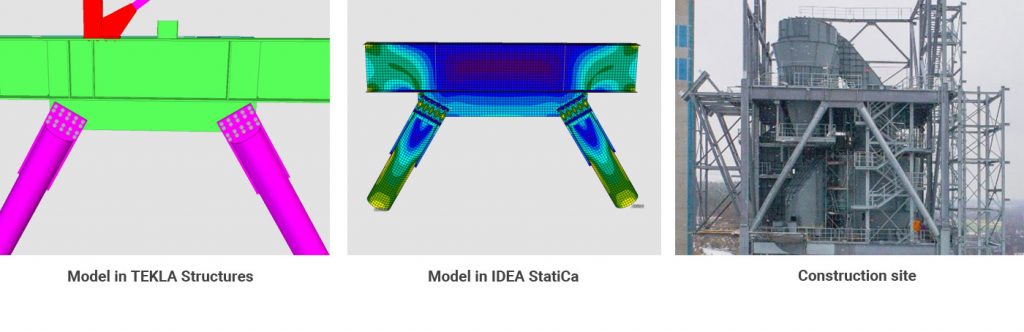

With the use of IDEA StatiCa software for the calculation of the connections of the project, many of the challenges that the design team had been facing before, were solved. Firstly, the 3D joint interface was vital to the best understanding of the static task that needs to be solved and it gave our team the capability to model in TEKLA Structures in a much productive way.

In addition, IDEA StatiCa provided us with the functionality to calculate load cases, which included biaxial moment and shear plus tension and torsion in an easy, straight-forward way which in the past had been a demanding and time-consuming task.

Moreover, Finite Element Analysis provides low-cost design solutions due to the fact that the design team had the complete control of every position of the connection investigated. By using this functionality the designer has been capable of reducing the material, welds and bolts in the areas that appeared less stressed resulting in a substantially limited cost in comparison with previous projects.

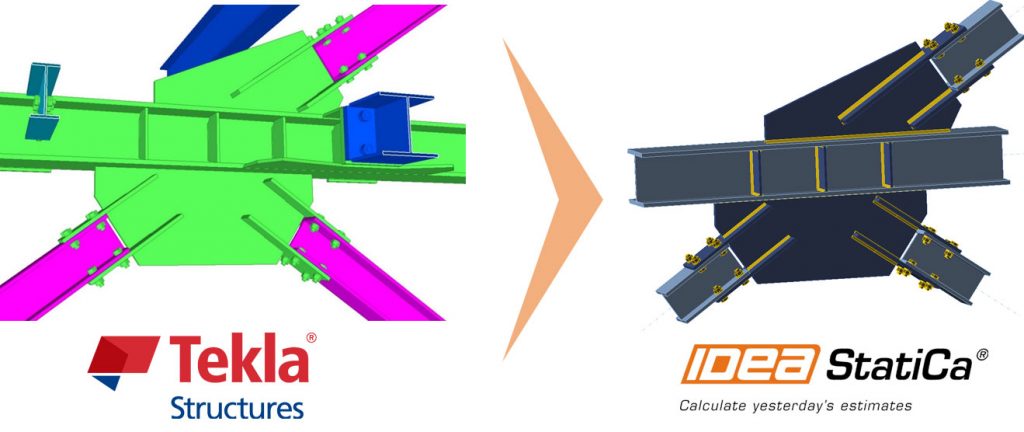

"One of the key advantages in using IDEA StatiCa has been the ease in solving “impossible” joint combinations; especially since IDEA StatiCa allows you to directly import the 3D connection design directly from Tekla Structures. This in turn leads to more accurate calculations and safer design (as estimations are eliminated). Consequently, the need to use oversized elements is negated and thus the final design is not only more economic but promotes sustainability as well."

Last but not least, IDEA StatiCa and Tekla Structures interoperability is one of the most significant functionalities, which has revolutionised the way the team has approached joint calculation and design. It was able to model connections in TEKLA Structures and calculate them in IDEA StatiCa almost simultaneously; speeding up the process and saving time for the project. In addition, the team was now capable to import and calculate complex connections with out-of-plane members in a structural analysis software which in the past would be impossible.

"An additional benefit in using IDEA StatiCa, was the ability to calculate quantities in the early stages of the project and this was valuable to the contractor and the client alike. By combining the data available from Tekla Structures and the data provided by IDEA StatiCa we have managed to derive a very accurate estimate of the final weight of the structure; not only as generic numbers but specific quantities per steel profile, number of bolts and volume and mass of welds."

About the authors:

Harris Kougkoulos

Harris is a Senior Civil & Structural Engineer with a MEng (First Class) degree from the University of Bradford. After several years in the UK, he moved to Greece where he works with SDENG a specialist consultancy undertaking detailed engineering in collaboration with various European firms with an emphasis in BIM.

Lefteris Koutsouros

Lefteris joined SDENG in 2015 and has participated in the detailed design of several structures in the sectors of Power and Industry. He serves the company as Design Team Leader and he holds a MEng degree in Civil & Structural Engineering from the University of Thessaly, Greece.

SDENG is the leading engineering firm in Greece, dealing exclusively with detail engineering services for major contracting and engineering companies around the globe. With a monthly design capacity of 5000 tons, SDENG can provide a vast amount of steel and detail engineering services, using the latest specialized software for Building Information Modeling (B.I.M).

The company provides engineering services for medium, large and super large scale structural steel projects. SDENG’s mission is to deliver exceptional ideas and solutions. Our work begins by understanding our client’s business, brand and mission. With a deep understanding of their challenges and the context in which they’re competing, we combine the knowledge, expertise and talents of our team to exceed their goals and set new standards.