Anchorage design of a steel spherical storage tank

The article discusses a case study on anchorage design on spherical tanks carried out by ODAN-DETECH Group Inc . It tries to provide an understanding of stress analysis and design of a generic Propane/Butane storage sphere in a high seismic area, highlighting the use of IDEA StatiCa software.

The project involves finite element analysis, code checks of a dome support system, and the design of a generic anchor system.

The Odan/Detech Group Inc. based in Ontario-Canada has been using IDEA StatiCa since the beginning of 2016, as one of our first clients in North America who recognized this exciting new technology that the software offers to structural engineers.

Since then, they have been using IDEA StatiCa extensively, and in this case study, they present a project that they have been involved: A Stress analysis and Design of a generic Propane/Butane Storage Sphere in a high seismic area. This analysis and design would determine if the structural support system contemplated will be adequate for the generic design loads, and this would allow for better budgeting of projects.

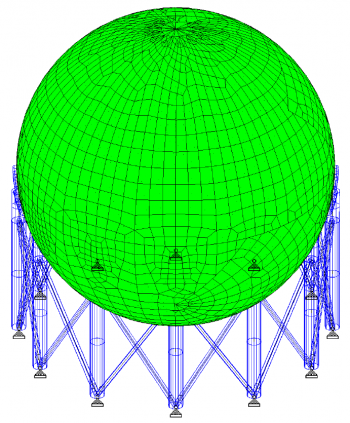

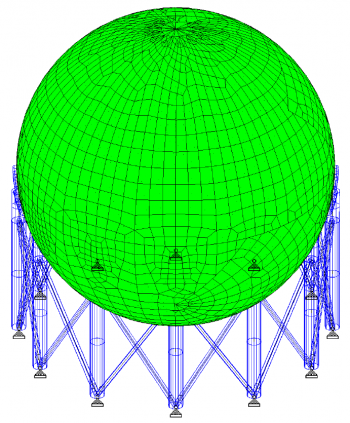

3D model of the main structure was made with a 3rd-party general FEA software

About the project

Some background on the anchorage design

Odan/Detech received design information for the Storage Sphere and outlined a general anchorage design procedure. They utilised general FEA (Finite Element Analysis) programs for analysing and designing the structure’s main body and employed IDEA StatiCa Connection for designing the anchor system.

Finite Element Analysis of sphere structure

The project involved calculating, with and without filled with liquid, using Finite Element models and two independent codes.

A short report was developed, illustrating the structural model, vibration modes, and also a summary of findings that were gathered form the two independent codes. Moreover, the project included the design of a generic anchor system.

Code check of dome support system

The analysis involved dead load, live load, wind load, and seismic loading, with load combinations following the AISC ASD standards. A code check was also conducted via AISC ASD, including an Euler buckling evaluation for the entire structure.

The project also involved design of a shear key at the column button. As a result, the team was able to develop a report that was prepared, detailed design and findings from these series of analyses.

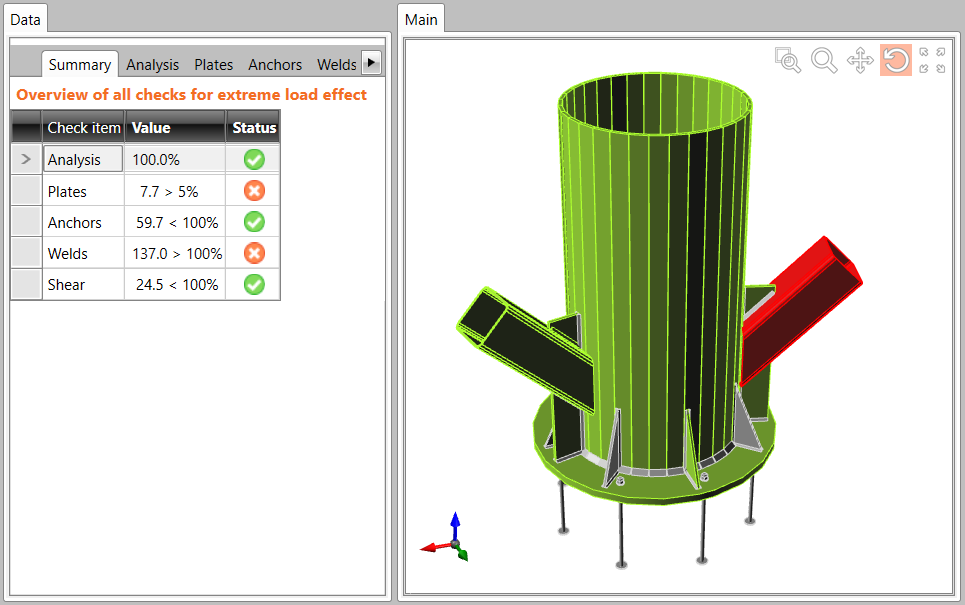

Anchorage design

Using IDEA Connection which utilizes the CBFEM (Component Based Finite Element Model) we were able to model many different components and geometries knowing that efficient use of material is assured.

The anchor joint could have been modeled in the traditional FEA programs, however even with the best of modelers the chore is enormous. IDEA StatiCa is specifically designed for steel joints. Changing stiffeners, member components, welds and bolts are routine in IDEA.

CBFEM method tries to create the model precisely. The analysis plate/walls are not interconnected, no intersections are generated between them, unlike the methods used when modeling structures and buildings. Mesh of finite elements is generated on each individual plate independently of the mesh of other plates. Welds are modeled as special massless force interpolation constraints, which ensure the connection between the edge of one plate and the surface/edge of the other plate.

The unique model of bolts provides excellent results – both from the point of view of precision and of the analysis speed. The method is protected by patent. The steel base plate is placed loosely on the concrete foundation. It is a contact element in the analysis model – the connection resists fully compression, but does not resist tension.

3D geometry Strain check Deformed mesh

Using IDEA StatiCa for Steel Sphere Anchorage Design:

We asked John Krpan a few questions about his experience on using IDEA StatiCa, and here are the answers:

How did you deal with similar connections in the past?

In the past, we created FEA models with Nastran and did the stress analysis. With simpler connections, we used spread sheets or a program called LIMCON.

Could you estimate the amount of time that it has saved you?

Using IDEA StatiCa we saved at least ¼ the time assuming you got it right the first time. LIMCON was limited to simple connections and couldn’t solve a complicated connection like this anchor.

Do you think that the use of IDEA StatiCa provides you more economical design? If yes, how is that?

For sure we get a more economical design. Based on our FEA experience you see the stresses visually. The effects of a stiffener are prominent. IDEA StatiCa makes the workflow process more efficient and adds the caveat of CODE checks!!

If you could choose only one, what would be the biggest advantage of

IDEA StatiCa?

by

John Krpan

M.S.C.E., P.Eng

President of ODAN-DETECH Group Inc.

About ODAN-DETECH Group Inc.:

The ODAN-DETECH Group Inc. is a multi-discipline consulting engineering firm with a staff that has extensive experience in Civil & Structural engineering, Building sciences, and the Construction fields. It was formed in 1992 by the amalgamation of the Odan corporation (formed in 1985) and Detech Engineering (formed in 1988).

Website: www.odandetech.com