The mysterious case of unaltered Bolt Stiffness under pre-tensioning

A lot of our users observed that when they attempted to change their connection bolts to pretensioned, the connection rotational stiffness remained essentially identical. As this is counterintuitive at first sight, our users turned to our support center, asking if there is a bug in the software – since one might expect the higher initial bolt tension to “tighten” the joint and therefore increase stiffness. In reality, however, stiffness predictions in Eurocode-based methods do not depend on the bolt’s initial pretension.

Preloaded Bolts

Before reviewing the code provisions, let’s revisit the basics. Preloaded (or prestressed) structural bolts – such as tension control bolts (TCBs) and high-strength friction grip (HSFG) bolts – are tightened to a specified preload so that the clamping force across the connected plates is well-defined and substantially higher than in a standard bearing-type bolt.

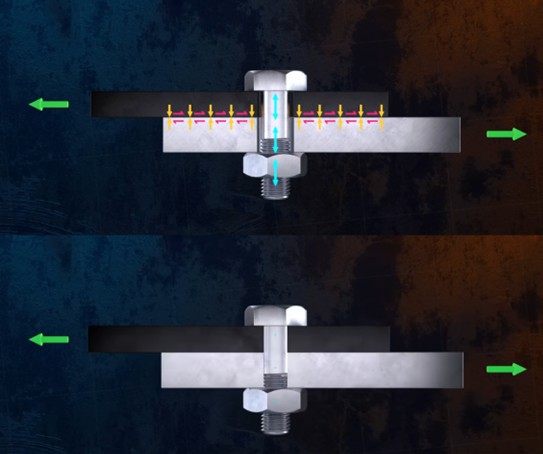

The key distinguishing feature is how load is transferred:

- Standard bolts transfer shear by bearing and axial force by bolt tension, where the initial tightening only ensures a snug fit or moderate pretension.

- Prestressed bolts in slip-resistant connections carry shear by friction between the faying surfaces, as long as the applied shear is below the slip resistance. The preload is therefore a functional design parameter.

Once slip occurs—or when the connection is designed as bearing-type despite using preloaded bolts—the mechanical behaviour becomes broadly similar to that of standard bolts. Prestressed bolts are predominantly specified for:

- Slip-resistant connections where serviceability slip must be prevented (bridges, crane runway beams, fatigue-sensitive structures, capacity-based seismic design),

- Connections requiring controlled deformation at serviceability, including some temporary works or dynamic applications,

- Structures where plate bearing or bolt hole deformation is undesirable.

They are not required for the majority of building frames or typical end-plate moment connections, which are rarely designed as friction-type joints.

Eurocode Stiffness Formulation

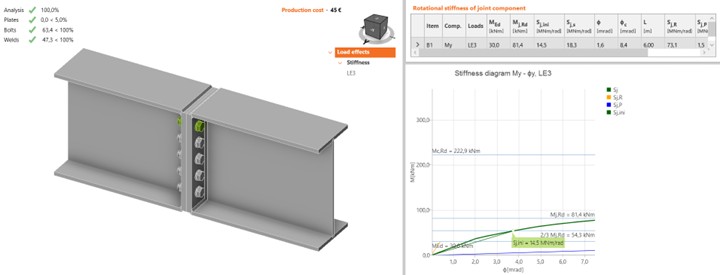

EN 1993-1-8 (Clause 6.1) defines the component method, where a joint is modelled as a set of springs representing the structural properties of the individual components that comprise the connection. Indicatively, we enumerate:

- the steel plates,

- the column web and flange,

- the end plate,

- and the bolt in tension.

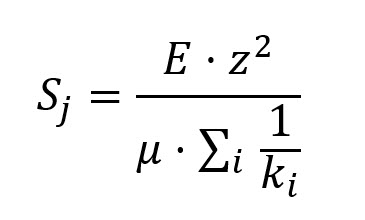

Specifically for rotational stiffness, each connection is decomposed into the specified components, and the stiffness of each component is calculated based on code-provided tables. Then, the beam-column or splice stiffness of the connection is assembled based on formula (6.27):

The bolt contributes through the stiffness of the tension component, denoted as ![]() , which is not modified for preloaded bolts and depends only on geometric parameters:

, which is not modified for preloaded bolts and depends only on geometric parameters:

· tensile area ,

· bolt elongation length .

Subsequently, Eurocode does not assign any additional stiffness due to bolt preload. As such, bolt pretension is not included in the stiffness calculation for moment-resisting joints.

This is consistent with guidance documents such as SCI P398 “Joints in Steel Construction: Moment Connections,” which emphasize that preload is not a stiffness parameter for component-calibrated joint models.

What’s cooking next (the 2nd Eurocode Generation)

In the 2nd generation of the Eurocodes, the principles of rotational stiffness calculation remain the same, with minor adjustments. The rotational stiffness assembly formula is identical (refer to EN 1993-1-8:2024 Annex B.4), replacing factor μ with η.

However, stiffness coefficients for bolts in tension now distinguish normal bolts from preloaded ones. For normal bolts, the proposed stiffness coefficient is identical to that in the current Eurocode generation (![]() ). For preloaded bolts, however, an adjustment has been proposed, and the recommended value for their contribution is , leading to a significant increase in the connection’s rotational stiffness.

). For preloaded bolts, however, an adjustment has been proposed, and the recommended value for their contribution is , leading to a significant increase in the connection’s rotational stiffness.

As we approach the release date of the latest generation of the Eurocodes, the IDEA StatiCa development team is working hard to incorporate the proposed code changes into our calculation core. As such, we expect to benefit from this code allowance and finally, calculate stiffer connections for preloaded bolt configurations.

Disclaimer: Bolt images were taken from this Efficient Engineer video