This question came up in a recent customer presentation and it immediately peeked my interest. This is not that an unusual request but one we do not hear very often. There may be several reasons for this one of them is education. This article aims to rectify that with an approach that is quick and efficient.

Nearly everything degrades over time and steel is no exception. There are measures that can be put in place to restrict the degradation for certain environments but most of the time for ‘normal’ steel structures these are not implemented. Steel structures usually have some form of protection but over time these also deteriorate which leave the steel exposed to the elements.

In that circumstance and over a prolonged period of exposure the steel rusts and delamination can occur. This results in section loss and hence, reduction in capacity.

IDEA StatiCa Connection is ideally placed to provide an estimation of this reduced capacity.

Methods

IDEA StatiCa Connection includes several analysis types built into its core. For a typical connection design we would be using stress/strain – the response of the joint to the applied loading conditions. In this case we will utilise the design resistance variant – the ratio between the design load and the maximum load for the whole joint. In these examples we are using a nominal applied load of 100kN shear and 100kNm moment.

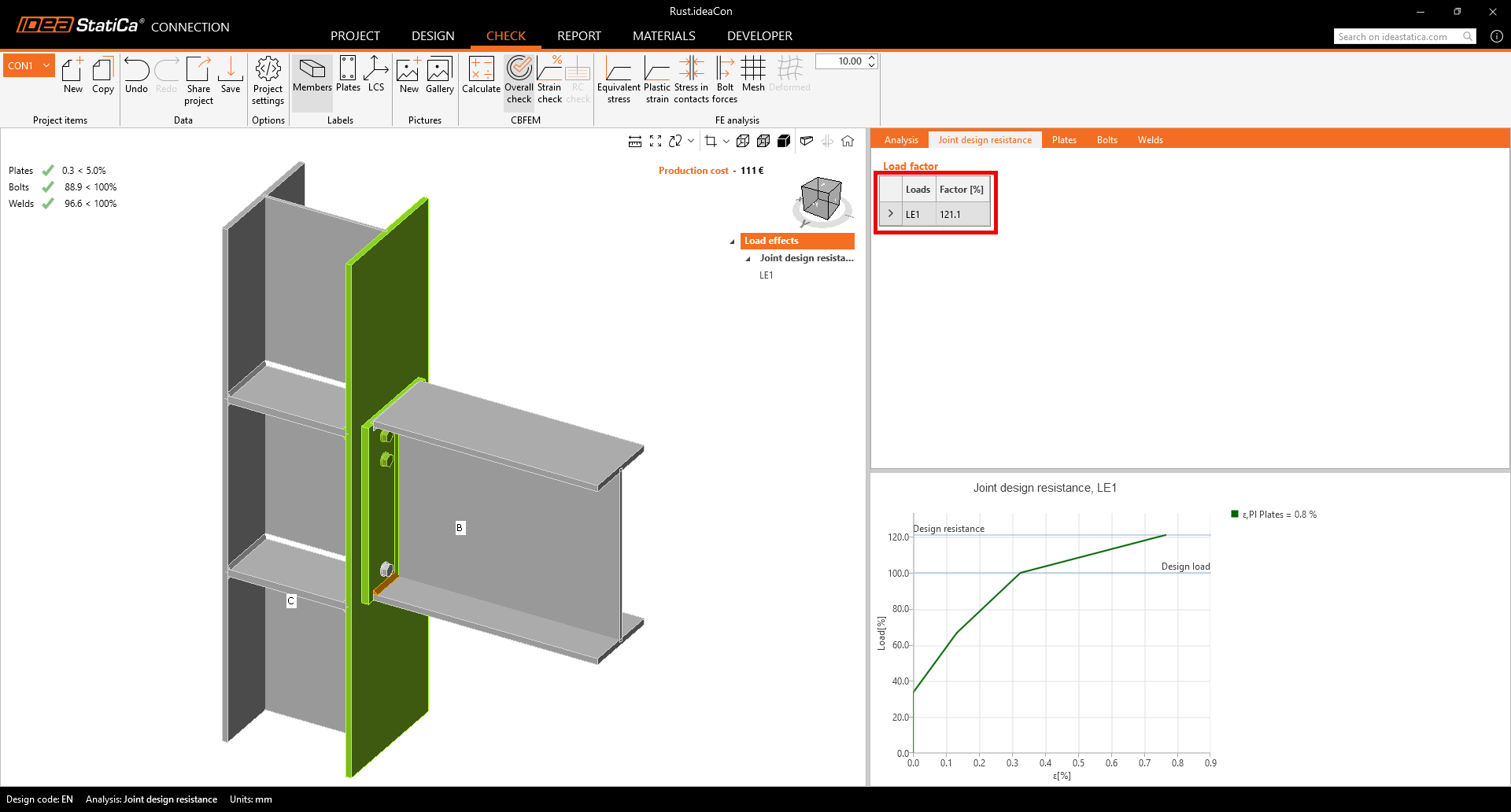

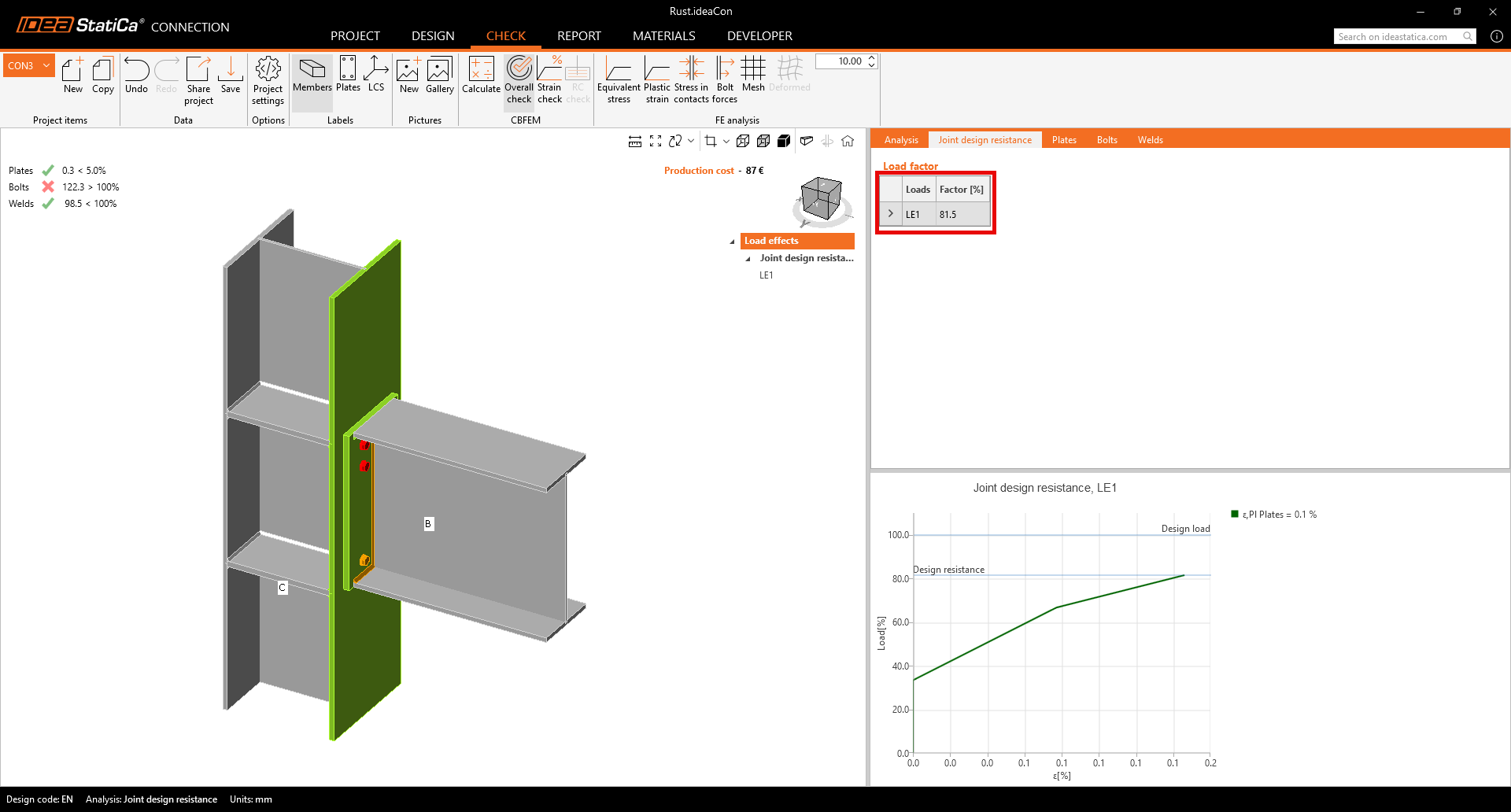

Consider a simple joint in a moment frame – as built:

This shows a capacity in excess of the design load effects (121%).

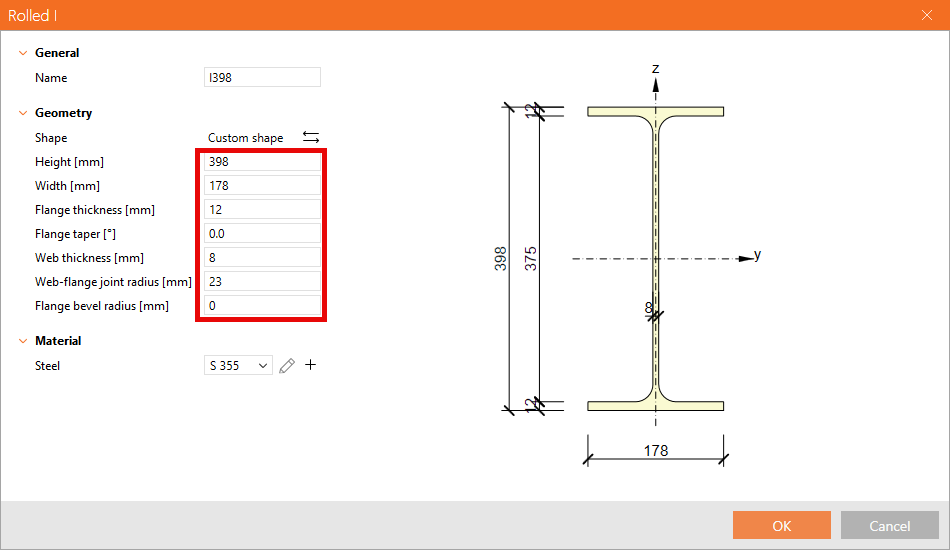

Given that we can inspect these joints to obtain actual data the section size itself can be modified by changing the dimensions associated with flange/web width and thickness:

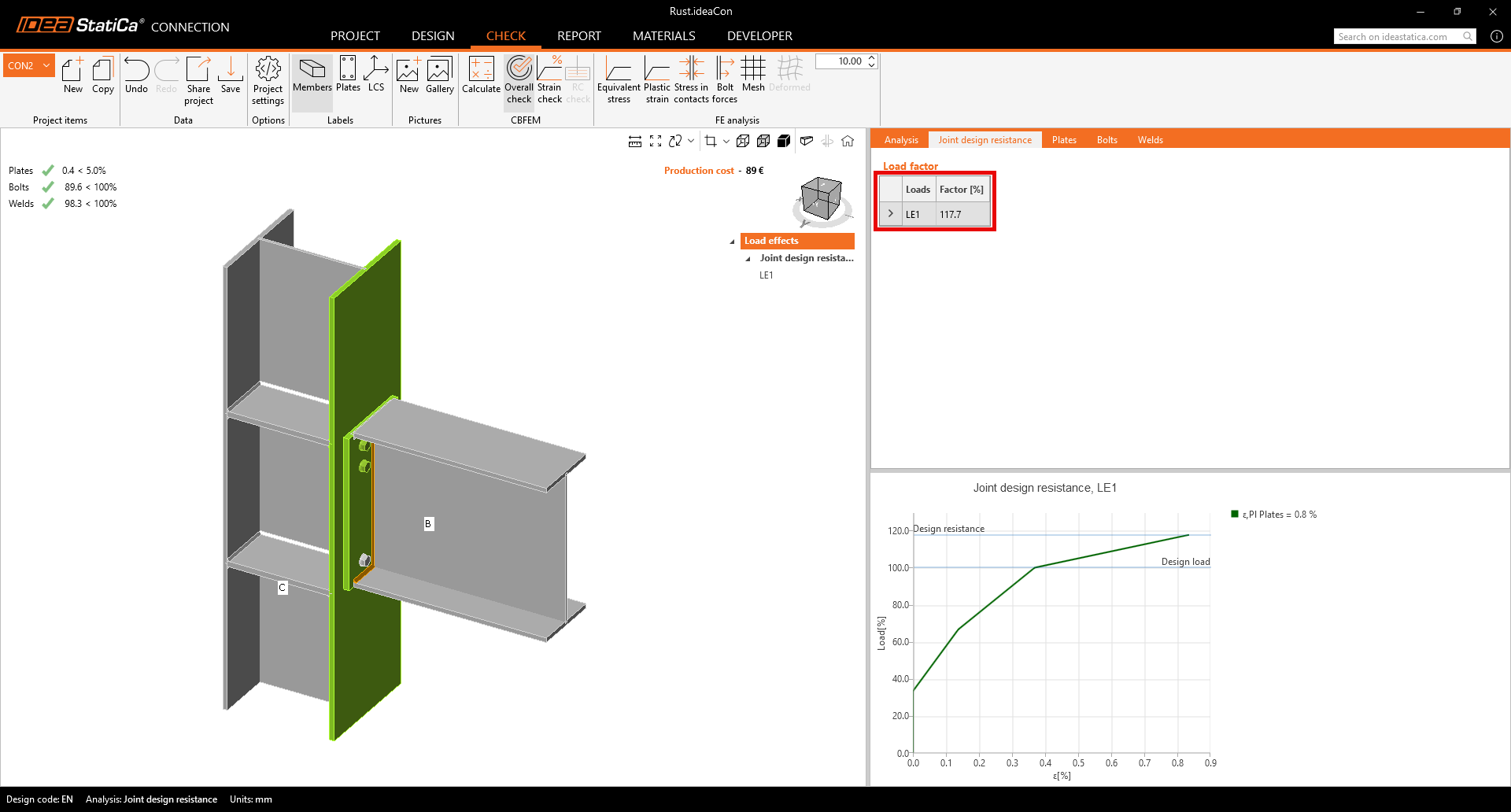

The same joint exposed for a period of ten years (say):

This still shows a capacity of in excess of the design loads but reduced by just over 4%.

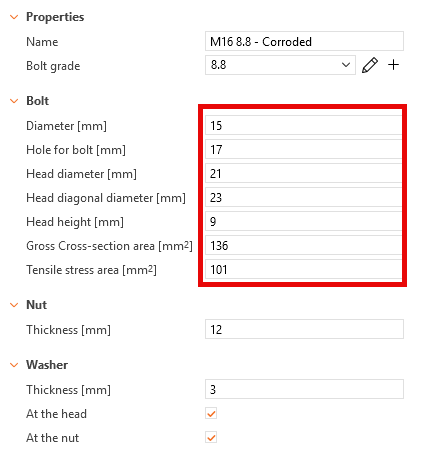

If the bolts were also examined and found to have a reduced diameter then we can also create a special bolt group:

Examining the same again but with bolt degradation gives us a failure emanating from the bolts and a much lower capacity (81%):

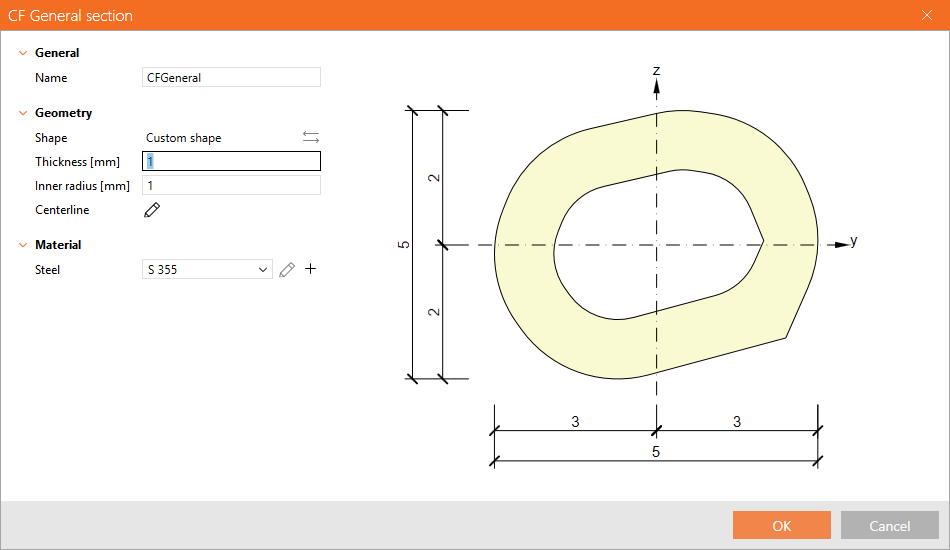

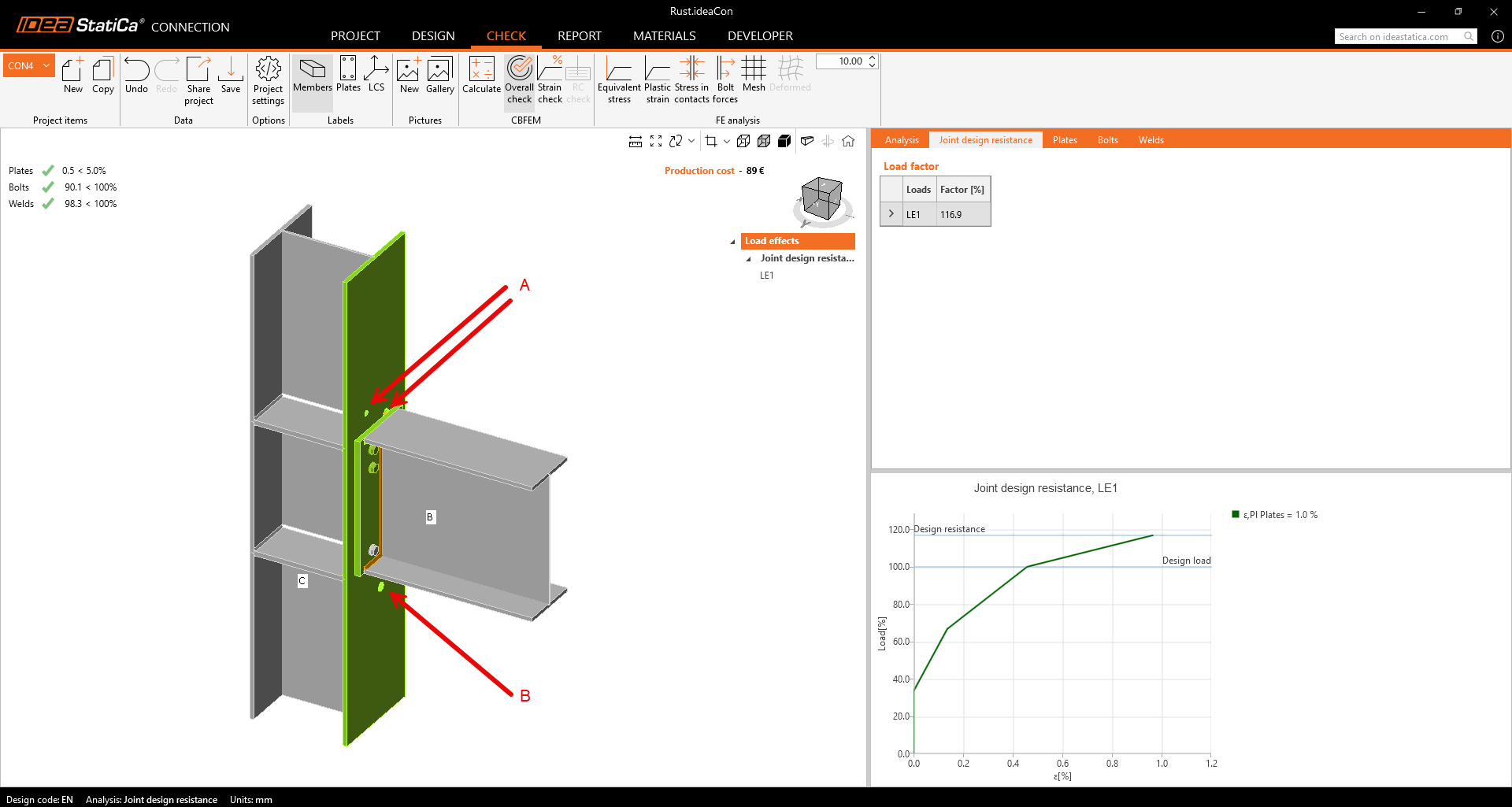

In very extreme circumstances rust can actually eat through steel so what can we do then? Modern methods now included the ability to laser scan these areas and read the resultant 3D models into many CAD/BIM solutions. If the area in question can be measured, then the same area can be added to the connection model as a void cut. We do this by tracing the affected area in a CAD/BIM application to create a dxf outline.

This can be read into the IDEA StatiCa Connection database as a section and removed from say the column flange as a void cut (A).

Alternatively, the area can be approximated to another of the in-built shapes and a hole created (B). Either way the connection arrangement can be checked. In this example only the missing volumes are modelled not the reduction in bolt capacity.

Conclusions

The resultant capacity estimation can be used to plan further maintenance or in the extreme remedial measures. The analysis features could also show that the structure is behaving much better than anticipated which again allows for a more realistic estimation for its design lifetime and maintenance.

The design resistance calculation has, more often than not, been thought of a tool for calculating how much capacity a joint has for taking increased load. In these circumstances though it can also be used to model existing conditions very quickly to ascertain if the structure can still take its design loads let alone any additional ones.

Using the options already built-in to IDEA StatiCa engineers can quickly assess the capacity of real-life situations very quickly.